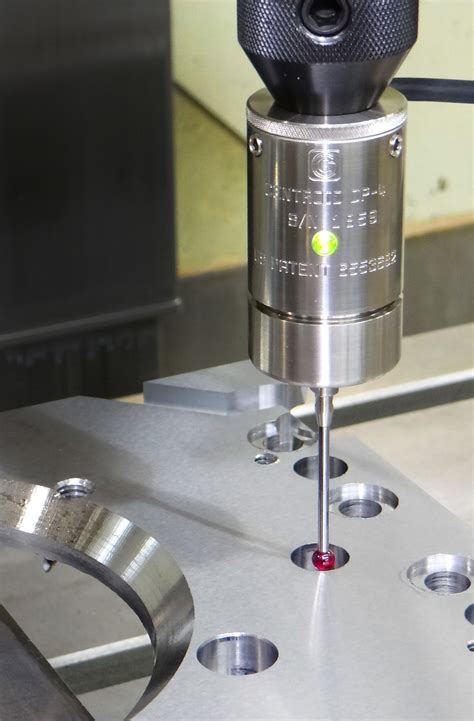

cnc machine probing The Haas Wireless Intuitive Probing System for lathes (WIPS-L) is a complete probing package that includes a turret-mounted probe and optical machine interface, along with powerful software that guides the operator through the probing process with intuitive, easy-to-use templates. Parts of a CNC milling machine include a column, base, knee, power feed mechanism, a work table, ram, spindle, milling tool, milling chuck, CNC controller, and an overhanging arm along with arbor support in case of horizontal milling machines.

0 · touch probes for cnc machines

1 · renishaw probes catalog

2 · renishaw probe tip catalog

3 · renishaw probe price list

4 · renishaw probe price

5 · renishaw probe for sale

6 · probe tool for cnc

7 · cnc tool setter probe

I’m connecting a hob cable to a 6mm via a whiska weatherproof junction box underneath the cooker. Do you know what gland sizes I need for the flat 6mm.

This article discusses probing in CNC machines, detailing what it is, probing techniques, types of probes, how probes work, and perhaps most importantly, the advantages and applications of probing in CNC machines.Renishaw offers a comprehensive range of probing and tool measurement systems for CNC machine tools. Designed to improve machining accuracy and efficiency, our automated systems deliver significant cost savings and quality .The Haas Wireless Intuitive Probing System for lathes (WIPS-L) is a complete probing package that includes a turret-mounted probe and optical machine interface, along with powerful software that guides the operator through the probing process with intuitive, easy-to-use templates.

Enhance the efficiency of your CNC machining centres and lathes with our innovative range of automated machine tool probes for workpiece setting and inspection. Streamline your operations and maximise your productivity with . In-machine probing doesn’t reach the power of CMMs but can still be useful for pre- and mid-process control, as well as for “rough screening” of parts. In-machine probing is a great inspection tool, but it cannot replace an . This article discusses probing in CNC machines, detailing what it is, probing techniques, types of probes, how probes work, and perhaps most importantly, the advantages and applications of probing in CNC machines.

Renishaw offers a comprehensive range of probing and tool measurement systems for CNC machine tools. Designed to improve machining accuracy and efficiency, our automated systems deliver significant cost savings and quality improvements.The Haas Wireless Intuitive Probing System for lathes (WIPS-L) is a complete probing package that includes a turret-mounted probe and optical machine interface, along with powerful software that guides the operator through the probing process with intuitive, easy-to-use templates.

Enhance the efficiency of your CNC machining centres and lathes with our innovative range of automated machine tool probes for workpiece setting and inspection. Streamline your operations and maximise your productivity with machine tool probing. In-machine probing doesn’t reach the power of CMMs but can still be useful for pre- and mid-process control, as well as for “rough screening” of parts. In-machine probing is a great inspection tool, but it cannot replace an overall inspection strategy. The machine tool probing systems can be used on CNC machining centers, lathes and more equipment to identify and set up parts, monitor workpiece surface condition, measure features, and verify finished part dimensions. The probe of machine tool is the best choice of machining complex curved surface.

touch probes for cnc machines

Probing systems for CNC machine tools can improve how you align and measure workpieces. An optical probe can also help you track tool wear. You can improve quality and productivity with an optical probing system. You can reduce scrap and lower your costs.CIMCO Probing automatically generates and inserts the machine-independant G-code directly in your NC program. Use CIMCO Probing to improve the quality of parts, increase productivity and reduce setup time and manual processes.The DATRON CNC Probe for surface mapping detects and compensates for irregular material surfaces. For milling or engraving on rounded surfaces, a probe like DATRON’s Z-Correction Probe is required and in many cases, a rotary axis is also necessary.Touch probes help reduce setup times, increase machine usage time, and improve the dimensional accuracy of the finished workpieces. Setup, measuring, and monitoring functions can be performed manually or—in conjunction with most CNC controls—can be controlled by .

This article discusses probing in CNC machines, detailing what it is, probing techniques, types of probes, how probes work, and perhaps most importantly, the advantages and applications of probing in CNC machines.Renishaw offers a comprehensive range of probing and tool measurement systems for CNC machine tools. Designed to improve machining accuracy and efficiency, our automated systems deliver significant cost savings and quality improvements.

The Haas Wireless Intuitive Probing System for lathes (WIPS-L) is a complete probing package that includes a turret-mounted probe and optical machine interface, along with powerful software that guides the operator through the probing process with intuitive, easy-to-use templates.

Enhance the efficiency of your CNC machining centres and lathes with our innovative range of automated machine tool probes for workpiece setting and inspection. Streamline your operations and maximise your productivity with machine tool probing. In-machine probing doesn’t reach the power of CMMs but can still be useful for pre- and mid-process control, as well as for “rough screening” of parts. In-machine probing is a great inspection tool, but it cannot replace an overall inspection strategy. The machine tool probing systems can be used on CNC machining centers, lathes and more equipment to identify and set up parts, monitor workpiece surface condition, measure features, and verify finished part dimensions. The probe of machine tool is the best choice of machining complex curved surface.

Probing systems for CNC machine tools can improve how you align and measure workpieces. An optical probe can also help you track tool wear. You can improve quality and productivity with an optical probing system. You can reduce scrap and lower your costs.CIMCO Probing automatically generates and inserts the machine-independant G-code directly in your NC program. Use CIMCO Probing to improve the quality of parts, increase productivity and reduce setup time and manual processes.

The DATRON CNC Probe for surface mapping detects and compensates for irregular material surfaces. For milling or engraving on rounded surfaces, a probe like DATRON’s Z-Correction Probe is required and in many cases, a rotary axis is also necessary.

renishaw probes catalog

3m tm scotchlok tm electrical idc 314 box

3-in-1 combination sheet metal machine

Using screws of the correct size will prevent the electrical box from becoming loose, which could lead to electrical hazards or poor circuit performance. The size of the screws required for an electrical box is primarily determined by the box's depth and the thickness of the mounting surface.

cnc machine probing|cnc tool setter probe